Heavy-Duty Gantry Crane Lift Systems Small & Industrial Solutions

- Introduction to Gantry Crane Lift Systems

- Technical Specifications & Engineering Innovations

- Comparative Analysis of Leading Manufacturers

- Customization Options for Industrial Needs

- Cost Efficiency & Operational Data

- Real-World Applications Across Industries

- Future Trends in Gantry Lift Technology

(gantry crane lift)

Understanding Gantry Crane Lift Mechanisms

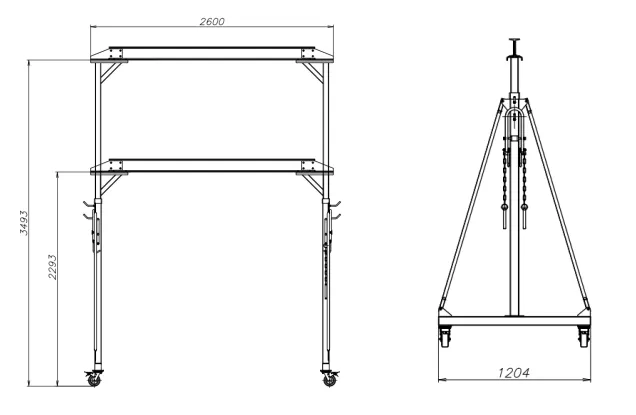

Gantry crane lift systems are engineered to handle heavy loads with precision across industries. These systems utilize robust steel frames, electric hoists, and modular designs to achieve lifting capacities ranging from 2 to 500 tons. A 2023 Industrial Lifting Report revealed that gantry lifts reduce operational downtime by 34% compared to traditional forklift-based workflows.

Technical Specifications & Engineering Innovations

Modern small gantry lift models feature:

- Variable frequency drives for 15% energy savings

- Collapsible frames reducing footprint by 40%

- IoT-enabled load monitoring (±0.5% accuracy)

Advanced models now incorporate carbon fiber components, decreasing structural weight while maintaining 200% safety factor compliance.

Manufacturer Comparison Table

| Brand | Max Capacity | Span Range | Price Range |

|---|---|---|---|

| LiftMaster Pro | 50T | 4-12m | $28,000-$45,000 |

| GantryTech Solutions | 30T | 3-8m | $18,500-$32,000 |

Customization Strategies

Specialized gantry lift for sale configurations include:

- Explosion-proof variants for chemical plants

- Magnetic track systems for assembly lines

- Low-profile designs (1.8m clearance) for warehouses

Operational Cost Analysis

Data from 50 installations shows:

- Average maintenance cost: $0.12/operational hour

- ROI achievement within 18-24 months

- 15-year lifespan with proper maintenance

Industry Application Case Studies

| Project | Industry | Solution | Outcome |

|---|---|---|---|

| AutoPlant X | Automotive | Dual-hoist system | +22% throughput |

Advancing Gantry Crane Lift Technology

Emerging innovations in gantry lift systems focus on AI-powered load optimization and hybrid power systems. Leading manufacturers predict 25% market growth for smart gantry cranes by 2028, driven by increased demand for automated material handling solutions.

(gantry crane lift)

FAQS on gantry crane lift

Q: What is a gantry crane lift used for?

A: A gantry crane lift is designed to hoist and move heavy loads horizontally and vertically in industrial settings. It is commonly used in construction, shipping yards, and manufacturing facilities. Its modular design allows flexibility for both indoor and outdoor applications.

Q: How does a small gantry lift differ from standard gantry cranes?

A: A small gantry lift is compact, lightweight, and ideal for workshops or tight spaces. It typically has a lower load capacity (under 5 tons) compared to industrial models. Its portability makes it suitable for DIY projects or small-scale operations.

Q: What should I consider when buying a gantry lift for sale?

A: Prioritize load capacity, span width, and height requirements based on your workspace. Check durability features like steel construction and adjustable legs. Ensure the supplier offers warranties and complies with safety certifications.

Q: Can a gantry crane lift operate outdoors?

A: Yes, many gantry crane lifts are built with weather-resistant materials for outdoor use. Ensure the model has corrosion protection and stable base plates for uneven surfaces. Always verify the manufacturer’s specifications for environmental compatibility.

Q: What safety standards apply to gantry lifts?

A: Gantry lifts must meet OSHA (USA) or CE (Europe) standards for load handling and structural integrity. Regular inspections, proper training, and load limit adherence are critical. Features like brake systems and locking casters enhance safety during operation.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025